We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for 2019 High quality Metal Stud C U Profile Light Keel Making Machine Light Keel Roll Forming Machine, Welcome to post your sample and color ring to let’s produce according on your specification.Welcome your inquiry! Hunting forward to building long-term cooperation with you!

We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for Profile Roll Forming Machine, Roll Forming Machine, Steel Tile Profile Roll Forming Machine, Our technical expertise, customer-friendly service, and specialized items make us/company name the first choice of customers and vendors. We’re looking for your inquiry. Let’s set up the cooperation right now!

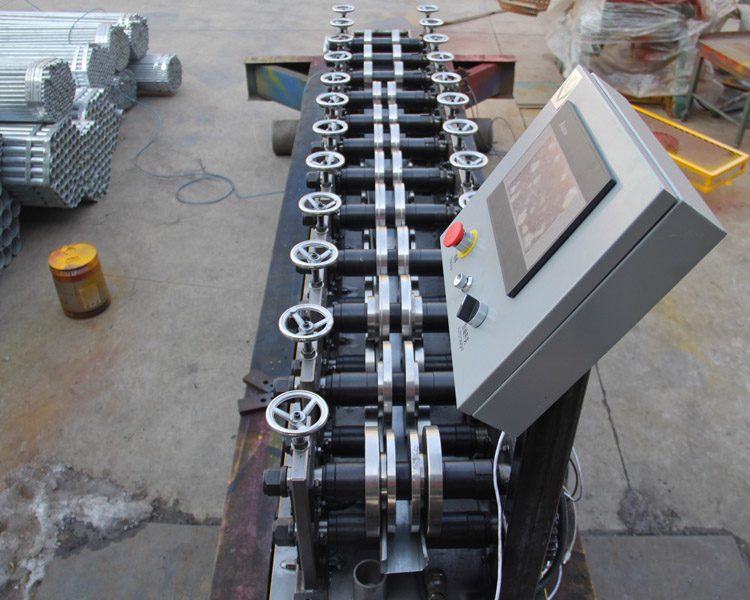

Equipment components of C channel light steel keel making machine:

Manual decoiling, roll forming machine, computer control system, hydraulic control system, cutting, run out table.

C channel light steel keel roll forming machine picture display

Packaging Details:

1. Machine is covered by plastic film

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).