We often stay with the principle “Quality Very first, Prestige Supreme”. We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for 2019 High quality Aluminium Steel Coils Roof Tile Roll Forming Machine, We believe in quality over quantity. Before export of the hair there is strict quality control check during treatment as per international quality standards.

We often stay with the principle “Quality Very first, Prestige Supreme”. We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for , With the intensified strength and more reliable credit, we have been here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We’ll endeavor to maintain our great reputation as the best merchandise supplier in the world. If you have any questions or comments, please contact with us freely.

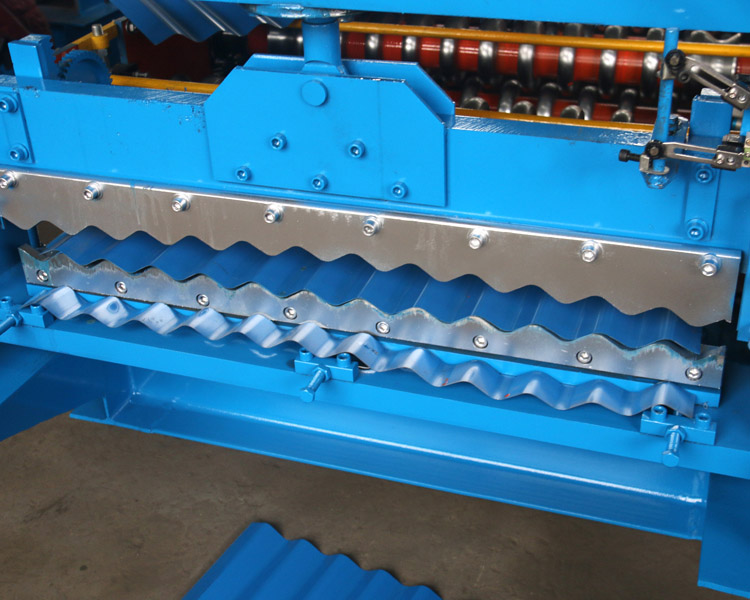

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

New Arrival China Stud And Track Light Steel Ke...

-

Chinese Professional China High Speed New Custo...

-

Factory directly Russia Popular Safety Door Fra...

-

2019 wholesale price China 1500mm Steel Coil De...

-

Metal profile light keel roll forming machine

-

PriceList for Latest Design Automatic Galvanize...