Our enterprise insists all along the standard policy of “product good quality is base of organization survival; client gratification could be the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff” and the consistent purpose of “reputation to start with, purchaser first” for 2019 Good Quality Roofing Tiles Press Forming Machine/colorful Tile Molding Machine, Our tenet is clear many of the time: to deliver top quality product or service at competitive price to consumers round the globe. We welcome opportunity prospective buyers to speak to us for OEM and ODM orders.

Our enterprise insists all along the standard policy of “product good quality is base of organization survival; client gratification could be the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff” and the consistent purpose of “reputation to start with, purchaser first” for Colorful Tile Molding Machine, Roofing Tiles Press Forming Machine, Tile Production Machine, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our merchandise are favored by domestic and foreign customers. With your support, we’ll build a better tomorrow!

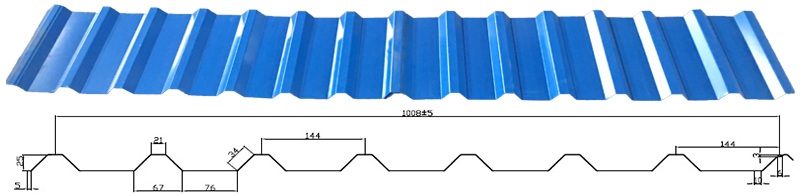

Trapezoidal Roof Tile Forming Machine is a very popular roof tile forming machine in Mexico. Roof tiles that are pressed as raw materials using color steel, GI, PPGI, etc. are an indispensable part of building construction.

The specification of Trapezoidal Roof Tile Forming Machine

| Item | Specification |

| Name | Trapezoidal Roof Tile Forming Machine |

| material | color steel, GI, PPGI |

| Processing thickness | 0.3-0.8mm |

| Diameter of shaft | Φ80mm |

| Electric tension | As the customer’s requirements |

| Roller | 45# steel chrome plating chromium |

| Processing precision | Within 1mm |

| Transmission | By chain link(1inch) |

| Hydraulic cutting | controlled by PLC |

| PLC | DELTA(TAIWAN) |

| Material of blades | Cr12 quenched |

| Switch | CHNT |

| Roller station | to the final design |

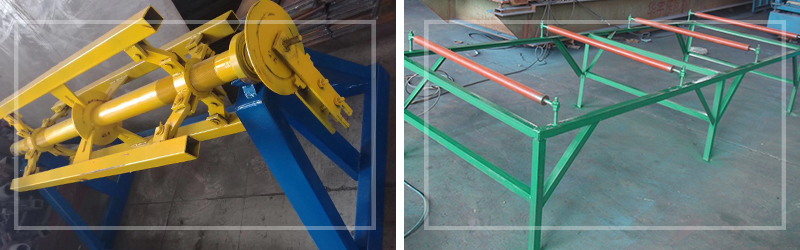

Main components of Trapezoidal Roof Tile Forming Machine

This machine is made up of roll forming machine, molding press, cutting machine, PLC computer control and hydraulic system.

| Decoiler | 1set | Above main components of our R101 roof roll-formed machine, and we adopt high-quality raw material to guarantee our machine long-life working. All electrical parts are famous brand. |

| Feeding & guiding device | 1set | |

| Main roll forming machine | 1set | |

| Hydraulic pressing system | 1set | |

| Hydraulic cutting system | 1set | |

| Controlling system | 1set | |

| Run out table | 1set |

We offer our customers easy-broken parts for free.

Application

Roof roll forming machinery could produce metallic roofing tile, trapezoidal or sinusoidal roofing sheet, floor deck, C and Z purlin, expressway guardrail, channel and stud, roller shutter and sandwich panel, etc. Customized profiles and requirements are acceptable, and assistant equipment such as hydraulic decoiler, auto stacker, etc.

Packaging details

1. Trapezoidal Roof Tile Forming Machine and uncoiler are nude packing (If you need, we can also packed it with water-proof plastic).

2. PLC control system and motor pump are packed with waterproof paper, spare parts in a carton box.

3. One set of machine needs a 40′ container to shipping.

Our Services

1. Warranty: two years, and we will provide technical support for the whole life of the equipment.

2. Delivery time: Within 30-45 days after deposit receipt your payment

3. Guarantee period: 18months free service/ pay service all the machine life

4. Installation and training If buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your workers/technician face to face. Without visiting, we will send you user manual and video to teach you to install and operate. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

FAQ

Q: Are you a trading company or a factory?

A: We are factory with the professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Does one machine can only produce one style panel profile?

A: Not exactly. For wider and double layer making machine. It can produce more than 3 kinds of panels.

Q: How long does it take to produce the machine?

A: Generally speaking, the machine can be completed within 20~45 working days. But if you need machines urgently, we can do our best to save you time.

Q: What can you do if the machine is broken?

A: The warranty period of our machine is 24 months, if the damaged parts can not be repaired, we can send new parts to replace the damaged parts for free, but you need to pay the courier fee yourself. If after the warranty period, we can resolve the issue through negotiation, we provide technical support for the entire life cycle of the device.

-

10 tons roll forming machine aluminum uncoiler

-

Roof tile making sheet metal machine aluminum d...

-

1000 Trapezoidal Metal Sheet Roll Forming Machine

-

2019 Hot Dipped Galvanized Steel Coil

-

2019 High Quality Glazed Tile Making Machinery ...

-

762 Corrugated Roof Metal Sheet Roll Forming Ma...

-

960 Glazed Roof Tile Sheet