We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for 2018 Good Quality Yx18-760 Roof Tile Galvanized Sheet Corrugated Panel Making Machine Hf, Our company eagerly looks forward to establishing long-term and friendly business partner relationships with clients and businessmen from all over the world.

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Corrugated Panel Machine, Galvanized Sheet Corrugated Panel, Roof Tile Sheet Machine, We will supply much better merchandise with diversified designs and experienced services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

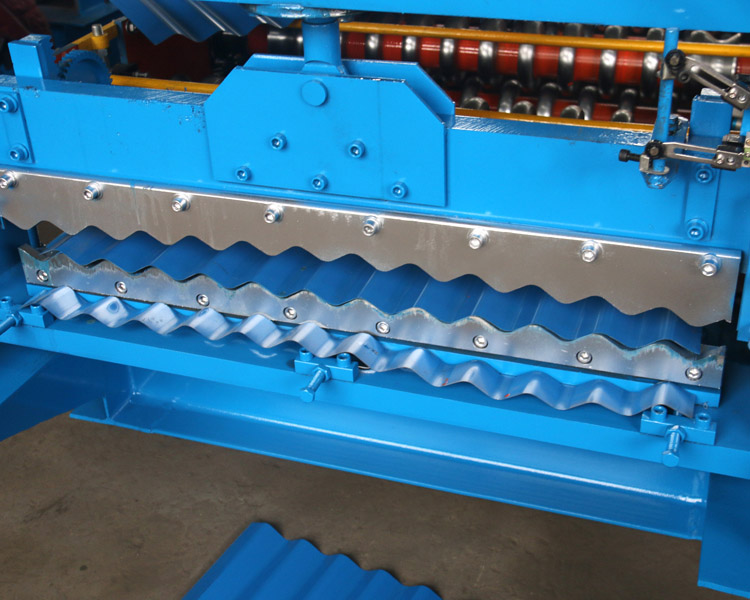

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

OEM Manufacturer Competitive Steel Coil Slittin...

-

PriceList for Punching Mould Cr12 Roller Shutte...

-

China Cheap price Galvanized Steel Deck Floor T...

-

OEM/ODM Manufacturer Strong Automatic steel coi...

-

Low MOQ for 10t Hydraulic Decoiler For Steel/al...

-

Chinese wholesale Speed Fully Automatic Trapezo...