2017 New Style Light Steel Kneel Roll Forming Machine - High Performance W12 Hydraulic Sheet Metal 4 Roller Rolling Bending Machine,4 Roller Bender 30×2000 – Haixing Industrial Detail:

We insist on the principle of development of ‘High quality, Efficiency, Sincerity and Down-to-earth working approach’ to provide you with excellent service of processing for High Performance W12 Hydraulic Sheet Metal 4 Roller Rolling Bending Machine,4 Roller Bender 30×2000, We warmly welcome all intrigued customers to speak to us for additional information and facts.

We insist on the principle of development of ‘High quality, Efficiency, Sincerity and Down-to-earth working approach’ to provide you with excellent service of processing for Hydraulic Sheet Metal Rolling Bending Machine, Rolling Bending Machine, W12 4 Roller Bender 30×2000, We have more than 8 years of experience in this industry and have a good reputation in this field. Our solutions have won praise from customers worldwide. Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us.

|

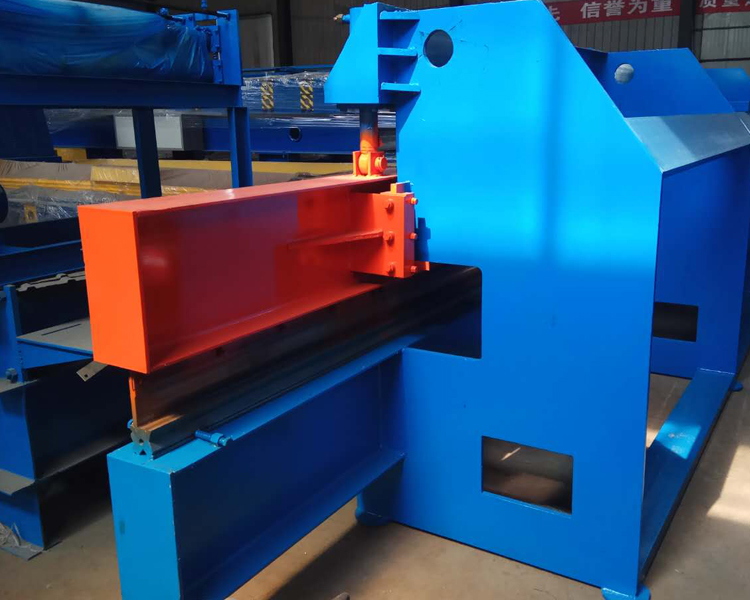

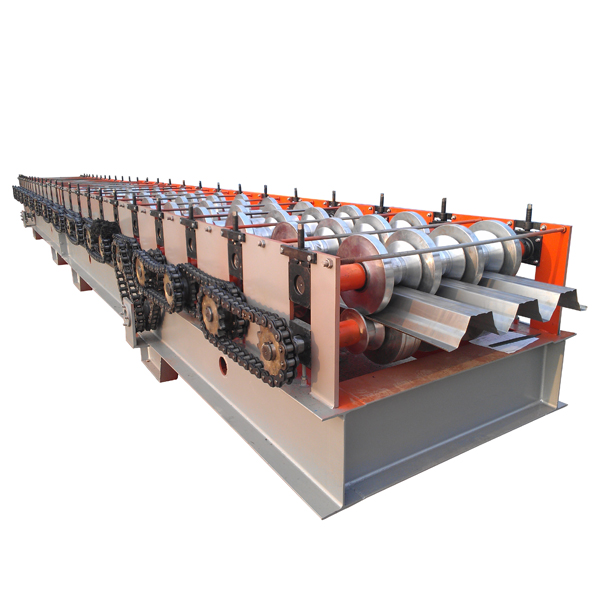

4 meters hydraulic roof sheet bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

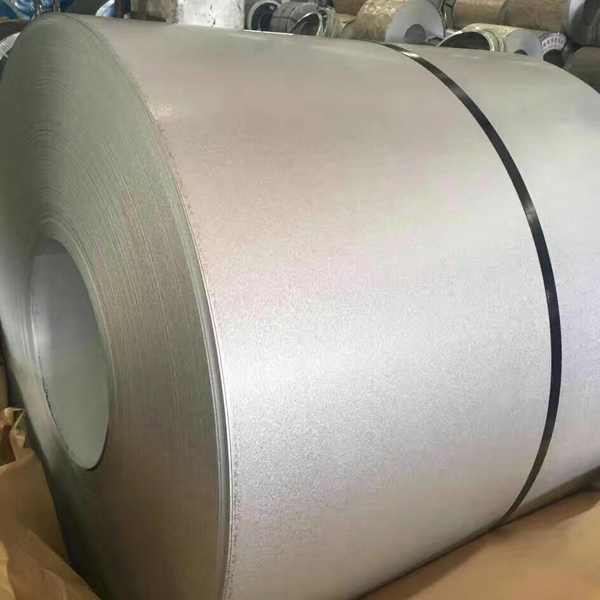

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

Carnival cruise ship rescues man who plunged from Norwegian vessel | Steel Downpipe Roll Forming Machine

Algeria Is Ready to Come Out of the Tourism Shadows | Roof Sheet Curving Machine

2017 New Style Light Steel Kneel Roll Forming Machine - High Performance W12 Hydraulic Sheet Metal 4 Roller Rolling Bending Machine,4 Roller Bender 30×2000 – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Well-designed Air Cleaning Filter - Trapezoida...

-

Factory Cheap Hot Sandwich Panel Manufacturing ...

-

Professional China U/Z/C Purlin Roll Forming Ma...

-

China New Product Roof Roll Machine - Automati...

-

High Quality for Auto Blade Bending Machine - ...

-

Original Factory Steel Plates - PU Sandwich Ro...