We delight in an exceptionally good popularity amongst our customers for our fantastic product high quality, competitive cost as well as ideal service for 100% Original Factory Yx 820 Colored Glaze Steel Metal Sheet Cold Roll Forming Machine For Roof And Wall Panel, We sincerely welcome overseas consumers to consult for your long-term cooperation as well as the mutual advancement.We strongly think that we will do superior and far better.

We delight in an exceptionally good popularity amongst our customers for our fantastic product high quality, competitive cost as well as ideal service for Roll Forming Machine, Roof Panel Roll Forming Machine, Wall Panel Roll Forming Machine, We are eager to cooperate with foreign companies which care much on the real quality, stable supply, strong capability and good service. We can provide the most competitive price with high quality,because we’ve been much MORE Specialist. You are welcomed to visit our company at any time.

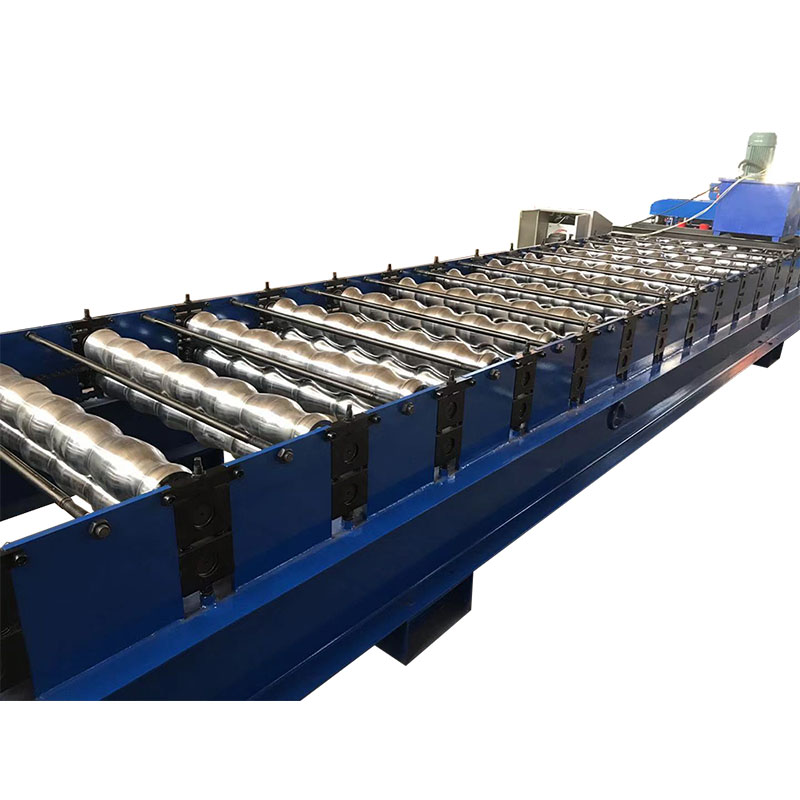

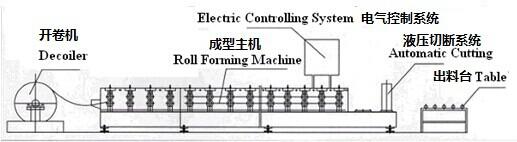

Main equipment of glazed tile color steel roof panel making machine: decoiler, main forming machine, hydraulic cutting, product stand, hydraulic system, electric system.

Uncoiler—-Guide—-Leveling—-Rolling—-Cutting Length—Output Table

This machine is made up of roll forming machine, hydraulic cutting machine, hydraulic station, PLC control system, product rack.

1) Number of forming steps: 17 steps

2)Material of shaft: 45# steel hardening and tempering treatment.

3)Material of rollers: high grade No.45 forged steel.

4)Main motor power: 5.5 Kw with cyclical planetary gear speed reducer.

5)Chrome surface thickness of the roller: 0.05 mm.

6)Main stand: 350# H steel welded structure.

7)Wall plate thickness: 16 mm the main frame.

8)Chain and gear move the line, motor drives. All working actions are controlled by PLC electric cabinet automatically.

9)Suitable power voltage: 380 V/ 60 HZ /3 Phase (can be designed according to buyer’s requirement).

10)Line working speed (Forming speed): about 15 m/min.

11)Dimension of the machine: about 9500 mm*1400 mm*1200 mm.

(2) Hydraulic Cutting Machine

1) Adopts post cutting, Stop to cut.

2) The cutting blade material is Cr 12 with quenched treatment.

3) Adopts welded frame for good rigidity.

4) The cutting frame is heat treated to avoid deformation of the final product. Cutting length tolerance ± 2 mm.

5) Cutting power is provided by the hydraulic station.

6) The final product can be cut in the PLC controller according to the set length, and the length is automatically measured by the encoder.

(3) Hydraulic station

1) It powers the hydraulic cutter.

2) All hydraulic fittings are made of Chinese famous brand products.

3) Hydraulic motor power: 3 KW.

(4) PLC Control System

1) This system uses a Panasonic PLC to control all work actions. The production quantity and the length of each piece will be measured automatically.

2) Panasonic converter speed control technology to achieve automated production.

3) Panasonic touch screen input and cancel work data.

4) Friendly human-machine interface system, which can set workpieces, length, quantity, etc. in batches.

5) Omron encoder counting, with the function of counting and measuring length.

6) Applicable power supply voltage: 380 V / 60 HZ / 3 phase (can be designed according to buyer’s requirements).

(5) Product Rack (un-powered)

1) When the product comes out of the cutting device, they are used to place the final product.

2) Two pieces, each piece length is 1 m, total length is 3 meters.

3) Collect the final product, which is convenient for workers to stack.

We have a professional loading technician to ensure that the goods are loaded into the container without any damage.

We have got the certification of ISO90001, SGS, CE etc.

Customers

Our customers trust our machines. Our products have been sold to the United States, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil and other places.

Services

The customer service department of Haixing Group consists of knowledgeable machine experts and technicians who can answer and submit solutions to customer problems in the fastest time.

For us, sales are not selling products, and then go away. Our aim is to serve our customers wholeheartedly. To this end, we offer our clients free advice.

In the communication with customers, we not only have an in-depth understanding of the actual needs of our customers, but also provide professional advice, including the choice of raw material types and raw material thickness.

We provide remote services to our customers, allowing them to purchase products without any worries.

Warmly welcome to visit our Chinese factory and choose the machine you need.

FAQ

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 18 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.

Our company adheres to the service tenet: quality first, reputation first. We believe that quality is the lifeblood of the company. We will provide satisfactory products and after-sales service for every customer.