Each individual member from our large performance revenue crew values customers’ needs and company communication for 100% Original Factory -end Low Roof Panel Ridge Cap Tile Machine, We’ve been not pleased while using the present achievements but we are trying finest to innovate to satisfy buyer’s much more personalized needs. No matter where you will be from, we have been here to wait for your sort ask for, and welcom to go to our manufacturing facility. Choose us, you can meet your trusted supplier.

Each individual member from our large performance revenue crew values customers’ needs and company communication for -end Roof Panel Ridge Cap Tile Machine, Low Roof Panel Ridge Cap Tile Machine, Roof Panel Ridge Cap Tile Machine, With the development of the society and economy, our company will continue the “loyalty, dedication, efficiency, innovation” spirit of enterprise, and we’ll always adhere to the management idea of “would rather lose gold, do not lose customers heart”. We’ll serve the domestic and foreign businessmen with sincere dedication, and allow us to create bright future together with you!

|

roof ridge making machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

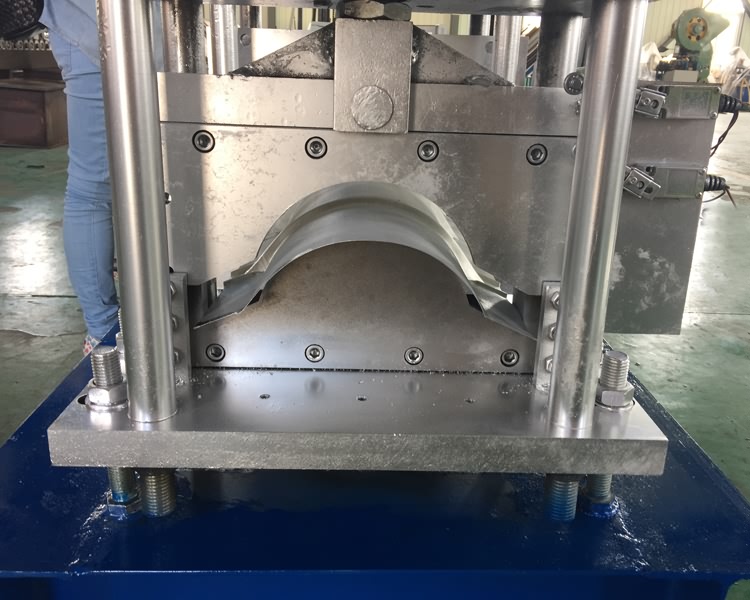

Machine details:

Roof ridge making machine package and shipment details:

Standard export packing: 1 x 40GP container, main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.