100% Original Aluminum Door And Window Frame Cutting Machine - Manufacturing Companies for Manufacture Sells Dw38cnc X 3a-2sv Cnc Pipe Bending Machine With Push Bending – Haixing Industrial Detail:

Our company aims to operating faithfully, serving to all of our customers , and working in new technology and new machine constantly for Manufacturing Companies for Manufacture Sells Dw38cnc X 3a-2sv Cnc Pipe Bending Machine With Push Bending, Seeing believes! We sincerely welcome the new prospects abroad to set up company interactions and also expect to consolidate the interactions with all the long-established clients.

Our company aims to operating faithfully, serving to all of our customers , and working in new technology and new machine constantly for Bending, Pipe Bending Machine, Push Bending, We aim to become the modern enterprise with the commercial ideal of “Sincerity and confidence” and with the aim of “Offering customers the most sincere services and best quality products”. We sincerely ask for your unchanged support and appreciate your kind advice and guidance.

|

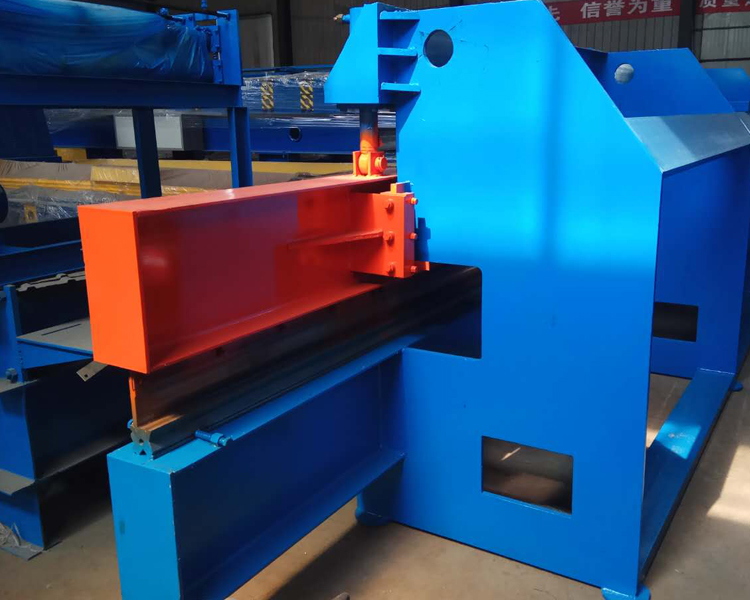

4 meters hydraulic roof sheet bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

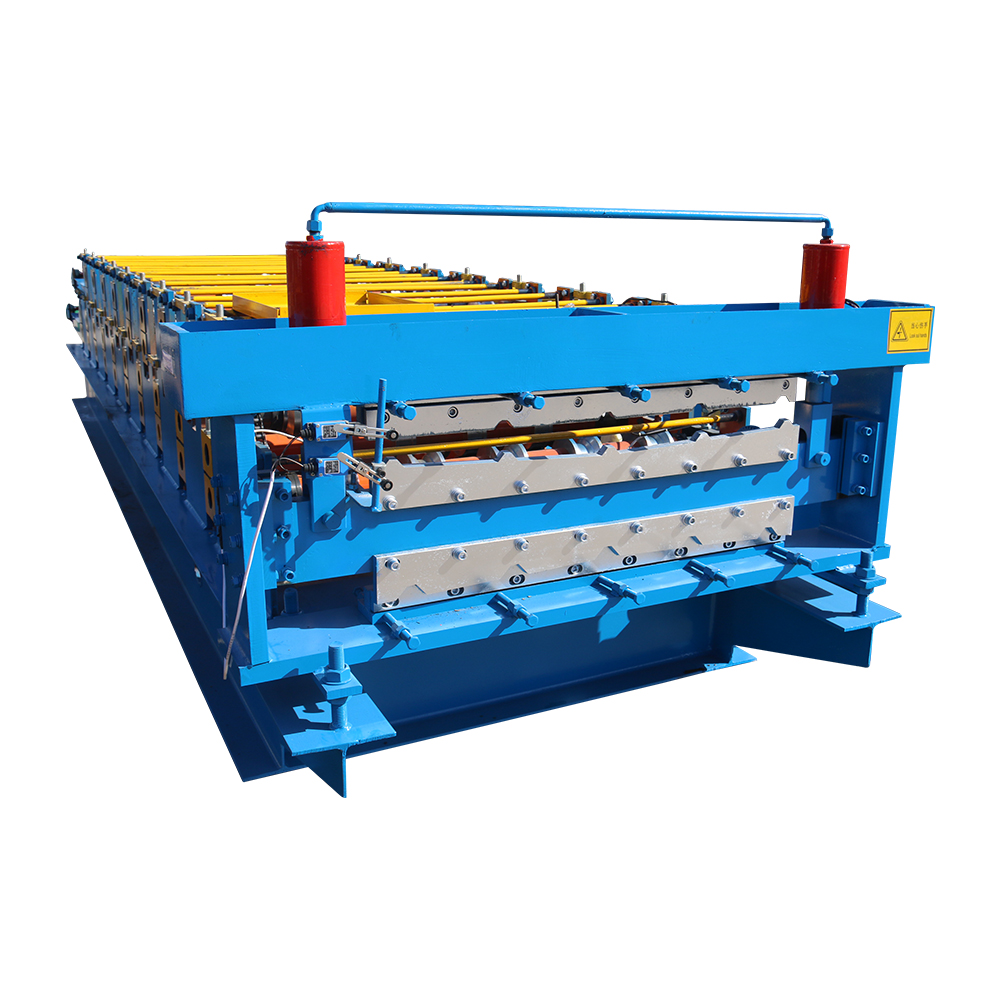

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

History of Botox-maker Allergan | Roof Sheet Curving Machine

Photos: PHOTOS: Today in History, December 27 – MetroWest Daily News, Framingham, MA | Ibr Roof Sheet Making Machine

100% Original Aluminum Door And Window Frame Cutting Machine - Manufacturing Companies for Manufacture Sells Dw38cnc X 3a-2sv Cnc Pipe Bending Machine With Push Bending – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Factory Price Curve Roof Machine - Leading Man...

-

Original Factory Metal Sheet Crimping And Curvi...

-

China Cheap price Used Z Purlin Roll Forming Ma...

-

Big Discount Roof Purlin Making Machine - Glaz...

-

Best Price for Cold Rolling Rebar Machine - Do...

-

Factory directly supply Roof Curving Roll Formi...